What is a casing schedule and who designs it?

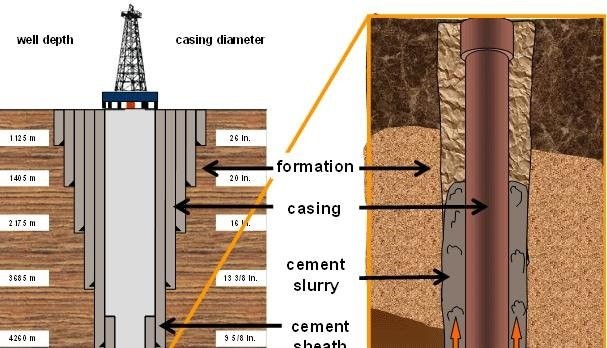

To keep loose sand and gravel from collapsing into the borehole, it is necessary to use well casing and screen. The screen supports the borehole walls while allowing water to enter the well; unslotted or blank casing is placed above the screen to keep the rest of the borehole open and serve as a housing for pumping equipment. Since the well screen is the most important single factor affecting the efficiency of a well, it is sometimes called the “heart of the well.”

Installation of well casing must avoid excessive bending or vertical (downward compressive or upward tensile stresses) that can deform or crack casing materials. Damaged casing can reduce the well’s integrity and make it difficult or impossible to install pumping equipment. It may also be difficult to remove equipment for well maintenance or equipment repair if the well casing is not installed properly. It is important to calculate this downward pressure when designing the casing schedule. Most casing manufacturers provide online databases to help determine what might be the best plan for the design for your well.

Here at Heritage Well our driller’s log formations, water encountered and drilling conditions while they are drilling the well. This data helps our drillers determine what this casing design should look like. Our drillers often train and calibrate their approach regularly with ownership to develop their skillset in this area. Our goal is always to cover the zones that will produce the most water with slotted casing to allow the water to come into the well.

Once we have achieved either contracted depth or client’s chosen depth our driller on site will develop a “casing schedule” that determines where both the perforated and solid casing will be installed. As we shared in a previous post we typically have more casing than we need on site in case of mishaps with manufacturing or delivering and keep extra perforated casing on hand as well. Each well bid is designed with 100 feet of casing to be installed unless otherwise requested.

After the driller has designed the casing schedule, he and his staff on site will organize the casing for installation for ease and to ensure success. You might see them line up the casing in a specific way, this is because they want to make sure what goes in the ground is what is intended and it needs to be reverse organized (bottom up). Casing is installed with splines. These splines adhere once piece of casing to another to keep the structure of the well together.

Comments

Post a Comment